Crusher Bearings ThomasNet

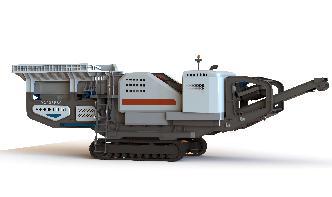

Designer manufacturer of bearings for jaw cone crushers used for crushing rock, ore stone. Specialize in ball bearings, radial roller bearings thrust roller bearings in different sizes styles.