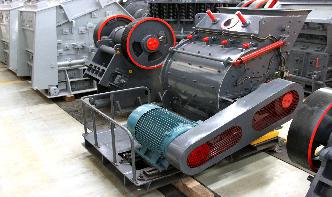

ball mill circulating load pdf

VRM and ball mill circulating load Page 1 of 1. Re: VRM and ball mill circulating load. Mainly in USA, the term circulating load is more often used than the circulation load is percentage of coarse return in relation to fines it can be calculated by : Coarse return TPH X 100 / Mill output range of cirulating load in a conventional close circuit ball ...